Technical Skills Development

Unlock your potential in industrial automation. Machinotech now offers expert-led, hands-on training for today’s most in-demand skills, including PLCs, HMI, Instrumentation, VFDs, Pneumatics, and Motor Control. Join us to build the expertise you need to advance your career.

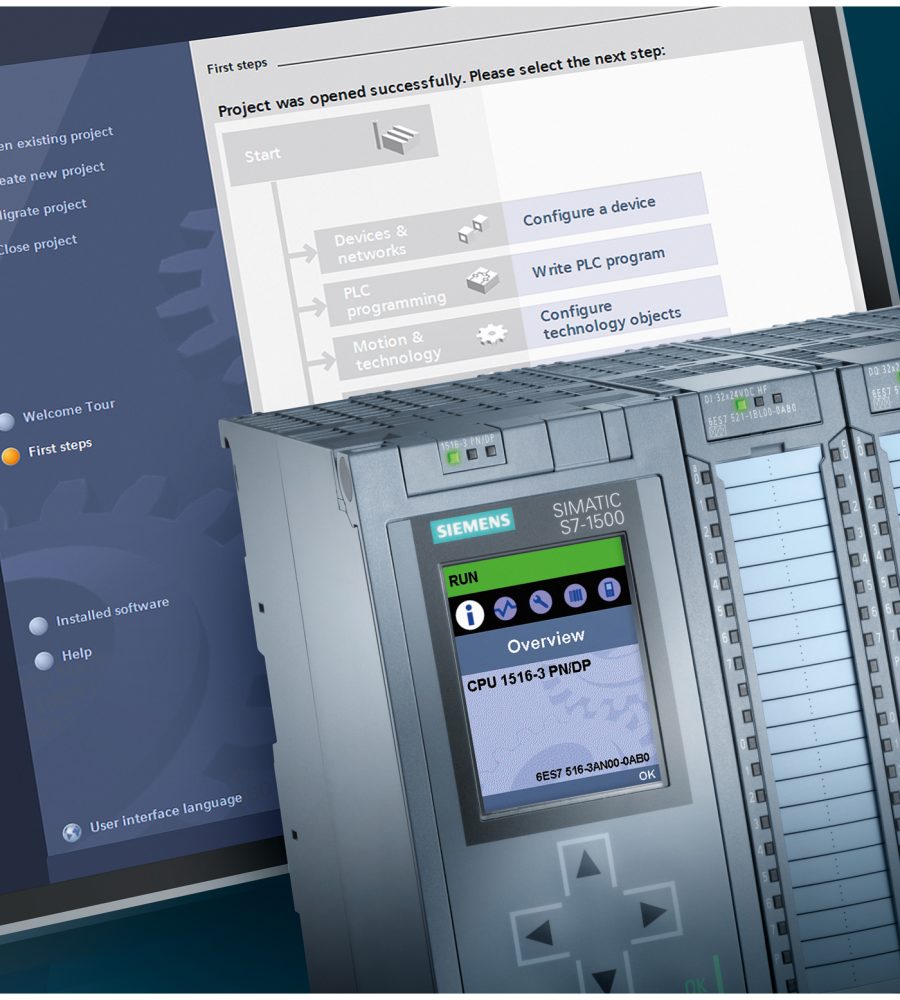

S7 1200 Basic Course

SIMATIC S71200 System Family Overview

Installation and maintenance of a PLC

SIMATIC S7-1200 software package

Hardware configuration

Hardware commissioning

Block architecture and Program Editors

Symbols

Binary and Digital Operations including IEC Timers and Counters

Introduction to Data Blocks

Introduction to HMI and Profinet networking

PLC and HMI tags

Program documenting, saving and archiving

Each of the above topic areas are backed up by practical exercises using a conveyor model and simulator. Working examples are provided and tested out during the course.

TIA Portal Programming 1

Overview and significant performance characteristics of the SIMATIC S7 system family

The components of the TIA Portal: STEP 7, WinCC, communication

Program execution in automation systems

STEP 7 block types and program structuring

Binary and digital operations

Programming of parameterizable blocks

Data management with data blocks

Programming organizational blocks

Test tools for system information, troubleshooting and diagnostics

Hardware configuration and parameterization of the SIMATIC S7–1500 modules, a PROFINET IO system (ET–200SP), a Touch Panel (TP 700) and a Sinamics G120 drive over PROFINET

Program documentation and saving

Deeper understanding of contents through practical exercises on TIA system model

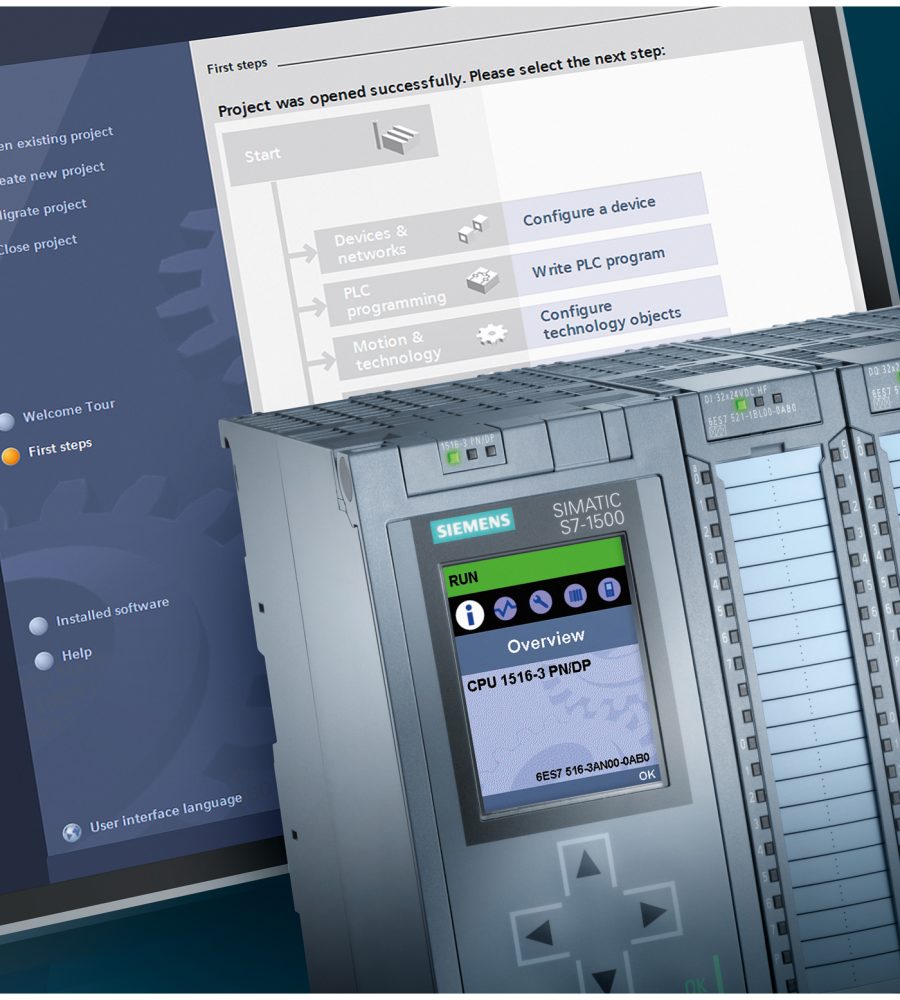

SIMATIC Programming 2

Use program design methods to structure the program

Solve extensive programming tasks with reusable blocks

Program advanced functions, such as indirect addressing, in STEP 7

Implement data management with the SIMATIC S7 automation system

Apply system blocks along with blocks from the standard STEP 7 library

Program classical software error handling and evaluation

Configure the connection of an operator control and monitoring system (HMI).

Configure TIA system components consisting of SIMATIC S7, HMI, PROFINET IO.

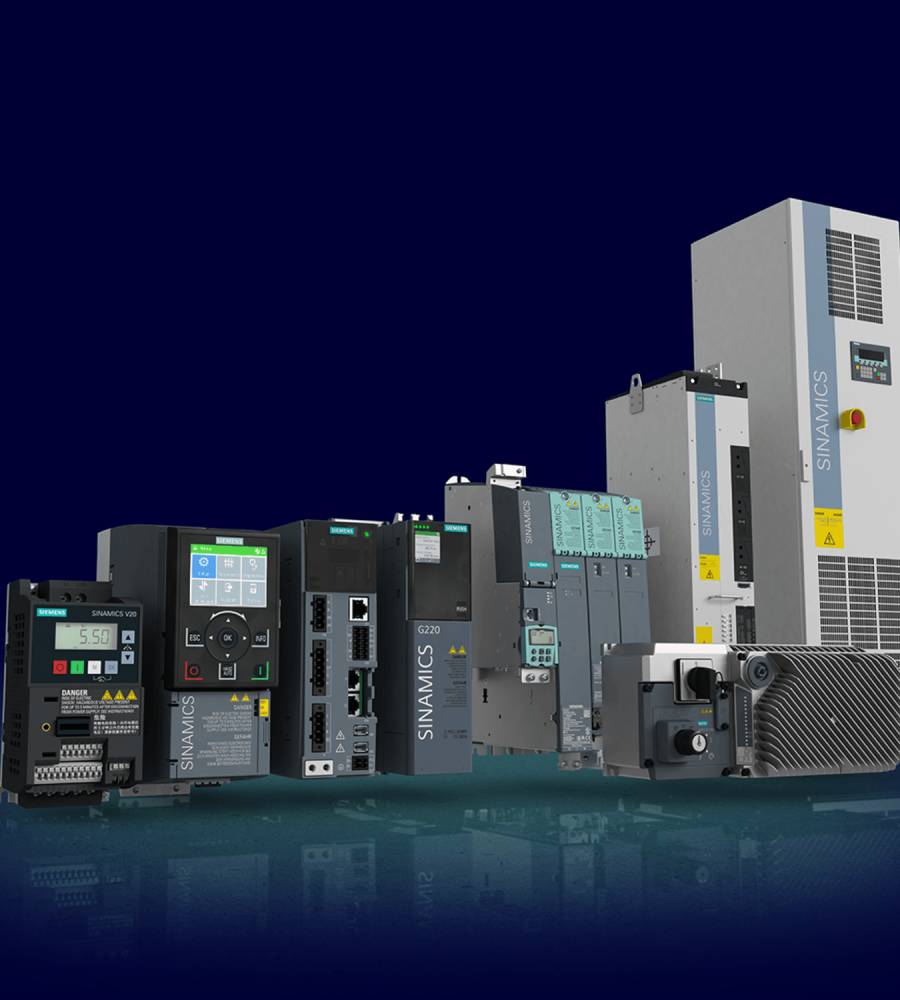

VFD Training Course – Siemens

Design of the System and Components

Electrical Basics Review

Different motor-starting methods

Incoming Power (line) Wiring

Motor (load) Wiring

Control Wiring

Keypad Controls

Terminal Strip Control – Automatic, Manual

Bus Communication Control

Open Loop Control

Manual Operation

Automatic Operation – 2/3 wire mode

References & Limits

Motor Speeds – Min, Max and Preset

Ramp Times

Speed Reference

Skip Frequencies

Inputs / Outputs Functions – Analog, Digital, and Relay

Application Functions

Reset

VFD Training Course – Danfoss

What is Local,2 wire and 3 wire Control why and where it is used (explanation)

Basic programming parameters and Local Control

2 wire control

Analog Input Control

Program Parameters

Preset frequency using digital input

Relay operation

Display Parameters, Terminal Parameters

3 wire control

Jogging using a digital input.

All advanced Parameters (Eg:- Skip frequency, Start at power up)

Other digital input parameters

Automatic stopping of the motor when the frequency exceeds a predefined limit

Practice Questions